《High-Precision Swivel Joint Solution: Innovative Bending Process Enhances Ball-Pass Performance and Service Life, Fully Compliant with API 16C Standards》

Published time:

2025-07-25

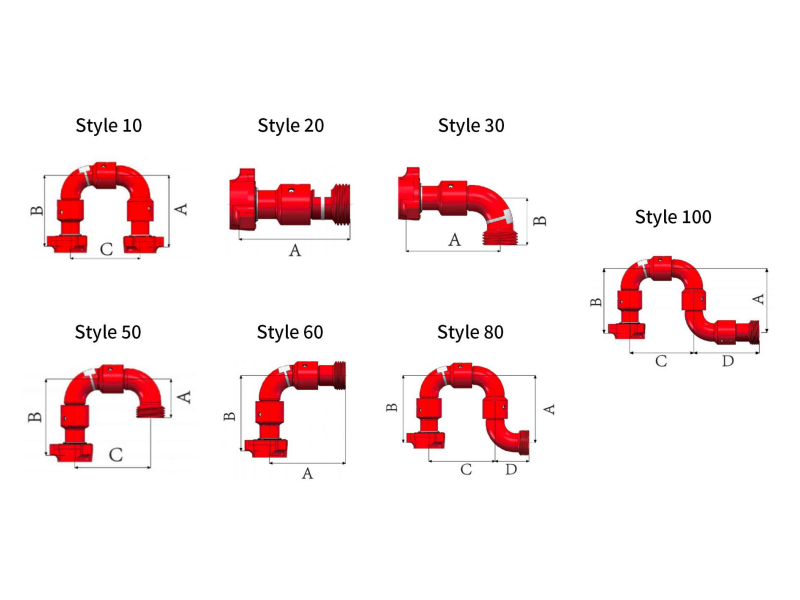

Swivel joints are key directional components in oil drilling fluid systems, bearing the crucial roles of flow control and impact buffering in high-pressure manifolds. In operations such as fracturing, drilling fluid transfer, and sour oil & gas gathering, their geometric accuracy and structural reliability directly determine system safety and maintenance costs. AIFUEL has developed a series of swivel joints addressing core industry challenges.

Swivel joints are key directional components in oil drilling fluid systems, bearing the crucial roles of flow control and impact buffering in high-pressure manifolds. In operations such as fracturing, drilling fluid transfer, and sour oil & gas gathering, their geometric accuracy and structural reliability directly determine system safety and maintenance costs.

AIFUEL has developed a series of swivel joints addressing core industry challenges. Covering nominal diameters from 2" to 4", these products strictly follow the API 16C well control equipment standards and offer more reliable directional solutions for high-pressure fluid systems through process innovation.

1. Geometric Precision Upgrade – Independently Developed Controlled Bending Process

·100% Design Compliance: Achieves full dimensional conformity of the elbow body with the design drawings, significantly increasing ball-pass rate to an industry-leading level.

·Full-Length Inner Diameter Consistency: Eliminates turbulence and erosion caused by traditional diameter transitions, thereby extending service life.

2. Enhanced Structural Design

·Stepped Ballistic Design in Swivel Section: Increases thickness in critical areas while maintaining overall weight, improving impact resistance.

·Metal Frame Packing: Greatly improves sealing performance and durability.

3. Deep Customization Services

Full-Process Engineering Adaptation:

·Custom options for different pressures, sizes, and connection types

·Anti-H2S special material selection

4.All-Scenario Maintenance Support:

·Reair kits include core components such as steel balls, ball plugs, and packings

·Emergency delivery available to prevent production downtime.

Related news